Small series and prototypes

Our know-how and many years of experience enable us to produce individual components, small series and prototypes to perfection.

Qualified employees implement your individual desires in superb quality on the latest up-to-date machinery. We are very pleased to provide you with support, if necessary, in the planning and design ready construction of your components.

Due to our high level of flexibility and an elaborate CAD/CAM system, we can even carry out complex orders at short notice

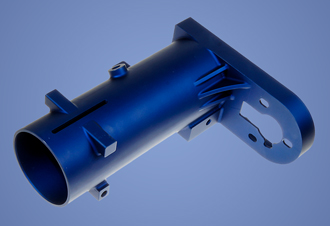

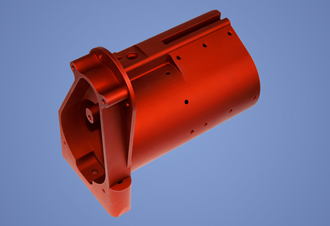

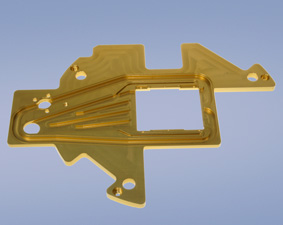

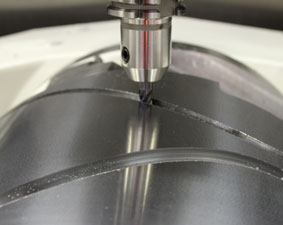

The images show current projects: aluminium prototype components milled to the highest level of accuracy out of a 3D piece (Length: approx. 30 cm) and color anodized:

Our service in manufacturing of prototypes and small series

- 3D milling of prototypes, individual components and small series

- Production for mechanical engineering, medical technology and laboratory devices among others

- All surface treatments such as colour eloxation, hard anodising, Teflon coating etc.

- Machining of stainless steel, aluminium, titanium and non-ferrous metal up to a size of 1500 x 750 x 700 mm

- Short processing time

- Certified according to EN9100:2018, ISO 9001:2015 and ISO 13485:2016

In overview of techniques in prototype and small series production

The following techniques are used primarily:

- 3-axis machining

- 5-axis machining

- Flat grinding

- Cylindrical grinding

- Wire eroding

- Sink eroding

We would be very happy to demonstrate our capabilities if you need any precision prototypes, individual components and small series made from metal.

We guarantee you: the highest quality, flexibility and speed.