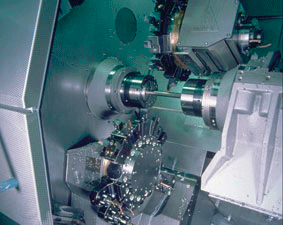

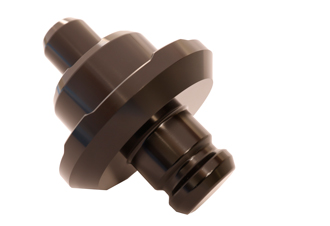

CNC turning, turn-mill parts

We can turn, mill, drill or interlock your complex items in one setting

Our main strengths are our flexible employees, immaculate quality and short delivery times

Components can be manufactured cost-effectively thanks to our synchronised double sided machining

Our service

- The latest twin-spindle machining centres enable synchronised and cost-effective double-sided machining

- Power-driven tools allow the complete manufacturing process to take place largely in one manufacturing cell

- Galvanising and thermal treatments: AWe take responsibility for carrying out any additional operations as desired

- Bar capacity: 2-80 mm

- Chucking work: up to a diameter of 450 mm

New turn-mill centres

distec ag has expanded its machine park with several turn-mill centres. The universal turn-mill centre DMG Mori NTX 1000 enables the highly efficient production of combined turn-mill parts in one clamping.

Details of our DMG Mori NTX 1000 turn-mill centres

- 5-axis simultaneous machining of complex workpieces

- Chain magazine with 76 tool places

- Turret with 10 driven tool stations

- Economical complete machining through counter spindle

- Bar feed up to max. diameter 65 mm

- KNOLL coolant cooler for constant coolant temperature

- Working area ø 10-320 x 400 mm

In overview

- Cost-effective manufacturing

- Series from 5 up to 300,000 pieces

- Bar capacity from 2 up to 80 mm

- Chucking work up to a diameter of 450 mm

- SPC monitoring