Quality Control | Measurement technology

As an ISO 13485:2016, EN9100:2018, ISO 9001:2015 and ISO 14001:2015certified company, we use all forms of modern quality management technologies.

We can guarantee a high and constant level of quality along with the consistent and permanent observation of each individual step of the process. The finished articles are checked in air-conditioned measurement rooms on 2D and 3D measurement devices using, for example, our modern "Zeiss Prismo 5HTG" CNC measuring machine.

Our well-trained measurement technicians originally come from production. They therefore know how a complex part is manufactured. With this professional experience, they support our production staff with targeted analyses for improvements.

All parts are washed and pre-air-conditioned before measurement. The modern equipped measuring room can maintain 20°C (± 1°C). The lighting allows visual checks at 1000 lux.

The proof of customer specifications is created on our two calibrated Zeiss measuring machines. All shape and position tolerances as well as the most modern requirements such as line shapes and free-form surfaces can be easily measured by scanning. The actual condition of your part can be visualised if required. This provides security in the evaluation of the conformity of your parts.

Accuracy of our Zeiss coordinate measuring machines (CMM)

Coordinate measuring machine Zeiss Contura with measuring range X=1000 mm, Y=1600 mm, Z=600 mm:

(1.7 + L/350) μm

Coordinate measuring machine Zeiss Prismo with measuring range X=700 mm, Y=900 mm, Z=500 mm:

(2.5 + L/300) μm

(L in mm)

Due to a monitored environment, professional working methods and state-of-the-art measuring technology equipment, you can trust our measurement results.

The distec quality assurance offers you

- Competent measurement technicians (Zeiss, AUKOM)

- Precise and regularly calibrated coordinate measuring machines (CMM)

- State-of-the-art environment and latest CMM software (Calypso 7.2, as of April 2022)

- Clear evidence of the conformity of your products

We are also happy to help you with part analysis or further development of prototypes.

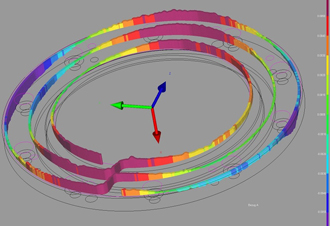

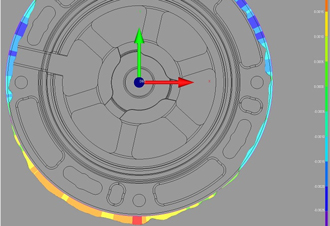

Examples of visualised measurements on CMM

Photo left, example 1 Plan area visualised with 7'500 points. Any distortion is easily recognisable and comprehensible thanks to the colour representation. The flatness of [target: 0.01mm] was not quite achieved, it can be reworked again..

Photo right example 2: Diameter visualised with 1'000 points. The desired roundness of [target: 0.005mm] is in tolerance. A small "egg shape" is visible, the measurement is trustworthy.

Certificates ISO 13485, EN9100, ISO 9001 and ISO 14001

View all certificates in the download area.